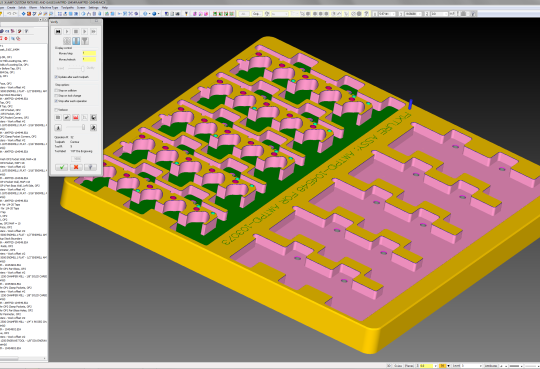

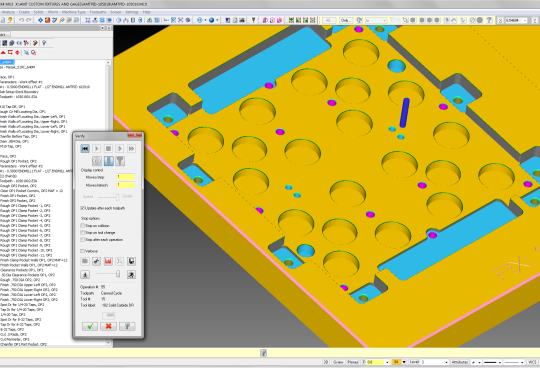

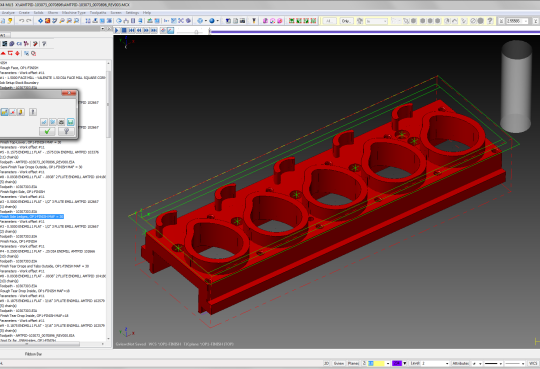

AMT utilizes leading CAM software with 3D part models to create all CNC programs. Each and every program is generated thru CAM and hand edits on the shop floor are not allowed. Not allowing hand edits assures CAM data integrity and eliminates the chance for errors and inconsistent production runs from one lot to another.

Through many years of experience we have tailored our CAM post processors to each of our machine tools.

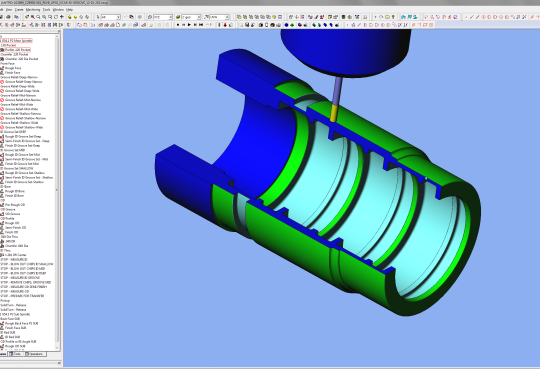

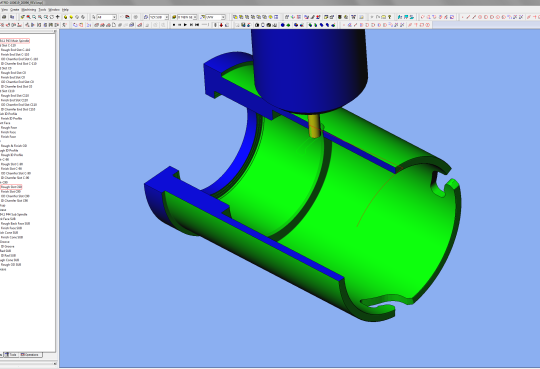

Our CAM software includes a graphical program verification tools which allows programmers to see errors on the computer before releasing CNC code to the shop floor. First time programs execute without costly mistakes and are 99% efficient right from the start.

The use of these tools in conjunction with standard operating procedures allows AMT to get new parts up and running quickly and efficiently.